- Machines

- Products

- Services

- Catalogs & Manuals

- Blog

- About

- Contact

Views: 161 Author: Site Editor Publish Time: 2023-12-27 Origin: Site

Article frame

1.Principle

2. Processing process

3. Machine advantages

4.CTAs

5. Recommended articles

For those who are using a thread rolling machine for the first time, or are planning to buy a thread rolling machine, you may have questions about "How to use the thread rolling machine?", then you have come to the right place! This article will provide a targeted answer.

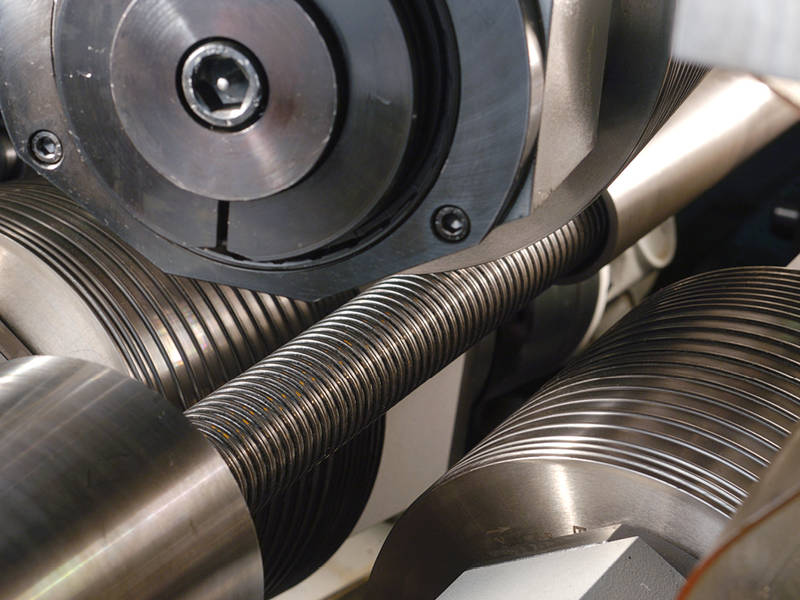

Thread Rolling Machine Operation Process A metal cold forming process that involves using a thread rolling machine to deform the workpiece material under high pressure so that the material flows and forms the desired thread profile.

1. Workpiece preparation:

Preparing a workpiece (usually a bar or blank) to the desired size and surface finish. It is then placed into the thread rolling machine's workpiece clamping system, which centers and holds the workpiece during the rolling process.

2. Thread rolling die settings:

The thread rolling machine is equipped with a set of thread rolling dies that have a reverse thread profile of the required thread. The mold is mounted on the rolling head or spindle of the machine. The rolling head applies pressure to the workpiece to form threads.

3. Feed and rotation:

The thread rolling machine advances the workpiece axially through the gap between the thread rolling dies. At the same time, the workpiece can also be rotated to ensure uniform thread formation.

4. Cold forming:

As the workpiece passes through the rolling die, the material is subjected to high pressure between the die threads. The pressure causes the material to plastically deform and flow, forming threads on the workpiece.

5. Final size and surface treatment:

Rolled threads may be slightly oversized depending on the rolling process. After the rolling operation, the threads may undergo additional sizing or finishing operations to obtain the desired size and surface finish.

6. End trimming and inspection:

After the thread rolling process is complete, the workpiece can be end trimmed to remove any excess material. Then check the dimensional accuracy and thread quality of the threaded workpiece.

1. Improve thread accuracy:

Thread rolling machines provide high precision and uniform thread profiles, ensuring consistent thread quality and minimizing the risk of thread errors or failures.

2. Faster productivity:

Thread rolling is a high-speed process that allows for faster production rates compared to other threading methods, thereby increasing overall productivity.

3. Cost-effectiveness:

Although the upfront cost is higher, thread rolling machines provide long-term cost savings due to reduced material waste, lower maintenance requirements and longer tool life.

4.Excellent thread surface finish:

Rolled threads have a smoother surface that reduces friction and improves the performance of threaded components in a variety of applications.

1. Excellent strength and durability:

Thread rolling machines produce threads of greater strength and durability than other thread forming methods. The rolling process displaces rather than removes material, resulting in improved fatigue resistance and a more reliable thread form.

Thread rolling offers significant cost advantages over other methods such as thread cutting or grinding. The rolling process is faster, requires less energy, and produces minimal waste. Therefore, it can reduce production costs and improve overall efficiency.

Thread rolling produces smoother, more precise threads for superior surface finish. This is especially important in applications where the threads must fit tightly or where aesthetics are important.

Unlike cutting or grinding methods, which subject the tool to severe wear, thread rolling places less stress on the tool. As a result, thread rolling tools last longer, reducing tool replacement costs and downtime.

Thread rolling machines provide highly consistent thread quality throughout the production process. The mechanical nature of the rolling process reduces the possibility of human error, resulting in uniform and high-quality threads every cycle.

Thread rolling machines can process a variety of materials, including: metals (carbon steel, stainless steel, aluminum, brass, copper, titanium, etc.), plastics, composite materials, hardened materials, heat-treated materials, high-tensile materials, etc. In order to ensure the accuracy and efficiency of thread rolling, as a manufacturer, you can send workpiece drawings or raw materials for trial operation of the thread rolling machine. As? ? Thread rolling machine experts will provide professional solutions based on raw material characteristics and expected applications, and are always happy to answer your questions.

If you are looking for such thread rolling machine, please contact us.

Email: ygmtools94@gmail.com